What is Stainless Steel? Stainless steel is essentially a low carbon steel which contains chromium at 10% or more by weight. It is this addition of chromium that gives the steel its unique stainless, corrosion resisting properties.

The chromium content of the steel allows the formation of a rough, adherent, invisible, corrosion-resisting chromium oxide film on the steel surface. If damaged mechanically or chemically, this film is self-healing, providing that oxygen, even in very small amounts, is present. The corrosion resistance and other useful properties of the steel are enhanced by increased chromium content and the addition of other elements such as molybdenum, nickel and nitrogen.

There are more than 60 grades of stainless steel. However, the entire group can be divided into five classes. Each is identified by the alloying elements which affect their microstructure and for which each is named.

Stainless steel is a preferred option when considering long term value for money due to its resistance to corrosion.

It is bright attractive appearance provides a modern and easily maintained surface.

Stainless steel is used in food industries, hospitals, kitchens, processing plants, handrails and balustrades, cladding, trench grates, architectural projects and building etc.

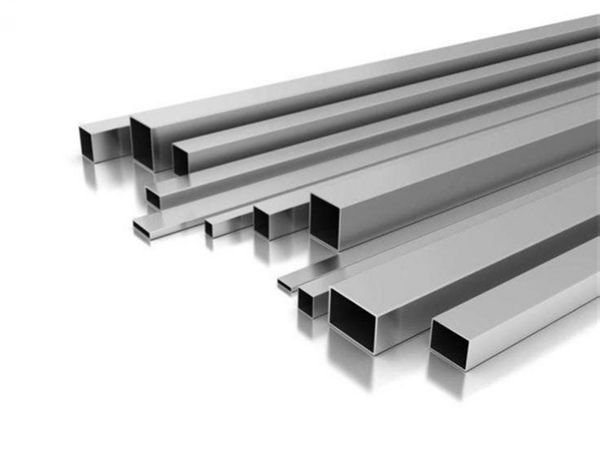

Stainless steel comes in a variety of products such as coil, sheet, plate, bar, fittings, tube, wire, fasteners and castings.

Stainless steels are iron-based alloys usually containing at least 11.5% chromium. Other elements, nickel being the most important, may be added in combination with chromium to obtain special properties. Stainless steels are highly resistant to corrosive attack and to oxidation at high temperatures. In general, resistance to corrosion and oxidation increases progressively, though not proportionately, with the increase in chromium content.

Stainless steel tube is used for many reasons: to resist corrosion, oxidation, and high temperatures, for cleanliness and low maintenance costs, and to maintain the purity of materials which come in contact with stainless. The inherent characteristics of stainless steel tubing permit the design of thin wall piping systems without fear of early failure due to corrosion. The use of fusion welding to join such piping eliminates the need for threading.

We can produce stainless steel tubing in many size and thickness with guaranteed quality. Please feel free to contact us. Our company offers the high quality Stainless steel tubing to suit different requirements and budgets. With rich experience in manufacturing Stainless steel tubing, our company has attached great importance to make innovations at Stainless steel tubing.

EASTEEL

EASTEEL