The popularity of stainless steel type is due to the resistive nature of stainless steel to corrosion and its ability to maintain integrity when other metal types would be compromised. Stainless steel tube/pipe is used in several different types of applications. Stainless steel is also less expensive than many other piping options, and can be easily cleaned and sanitized if needed.

304 and 304L

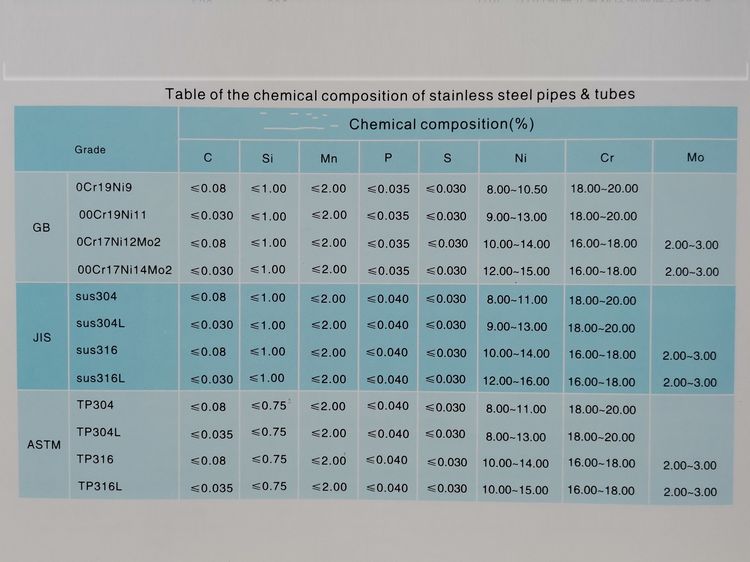

For stainless steel tubes/pipes to be classified as 304 type stainless steel it must have a carbon rating of .08 per cent or less. The 304 stainless steel type is used for general corrosive resistance. It is approved for uses below 800 degrees Fahrenheit. Using the 304 type of stainless steel at levels above this may result in early failure at the welded joints due to carbide precipitation. This type of stainless steel is commonly used in chemical plants, refineries and food processing locations. Stainless steel 304L has a carbon rating of .03 per cent or less. The reduced carbon rating of 304L allows it to be used in circumstances where the stainless steel pipes will be welded in corrosive conditions. The 304L type of stainless steel isn’t recommended for use at temperatures above 800 degrees Fahrenheit due to the potential of the risk of compromised integrity.

316L

The 316L type of stainless steel as a carbon rating of .03 per cent or less. The properties of the 316L allow it to be used in welded pipe assemblies without requiring a heat treatment after welding. The 316L type of stainless steel is commonly used in paper industry and in chemical plants.

EASTEEL

EASTEEL